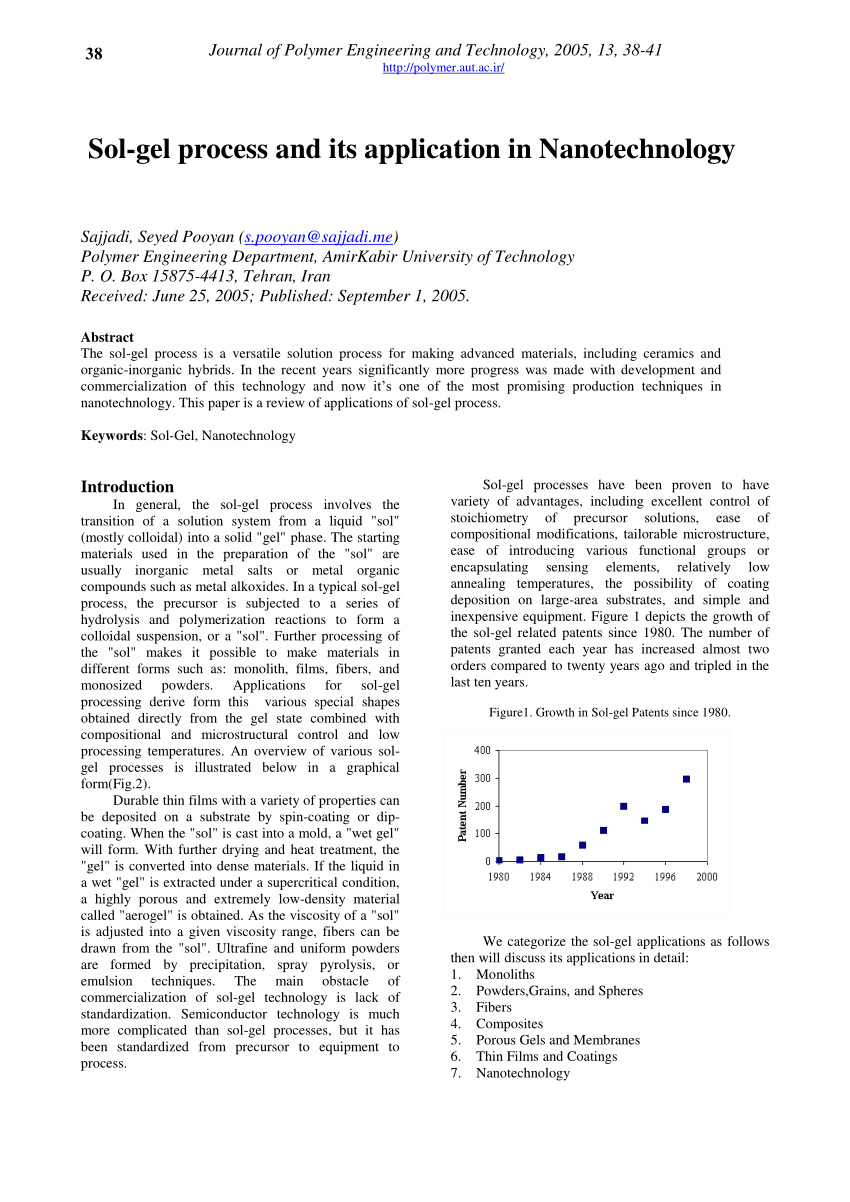

So Gel Process For Ceramic Coatings

What is sol gel ceramic coating.

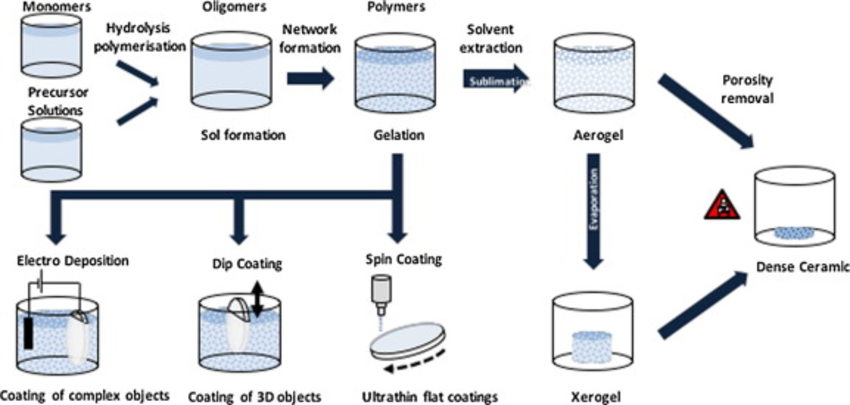

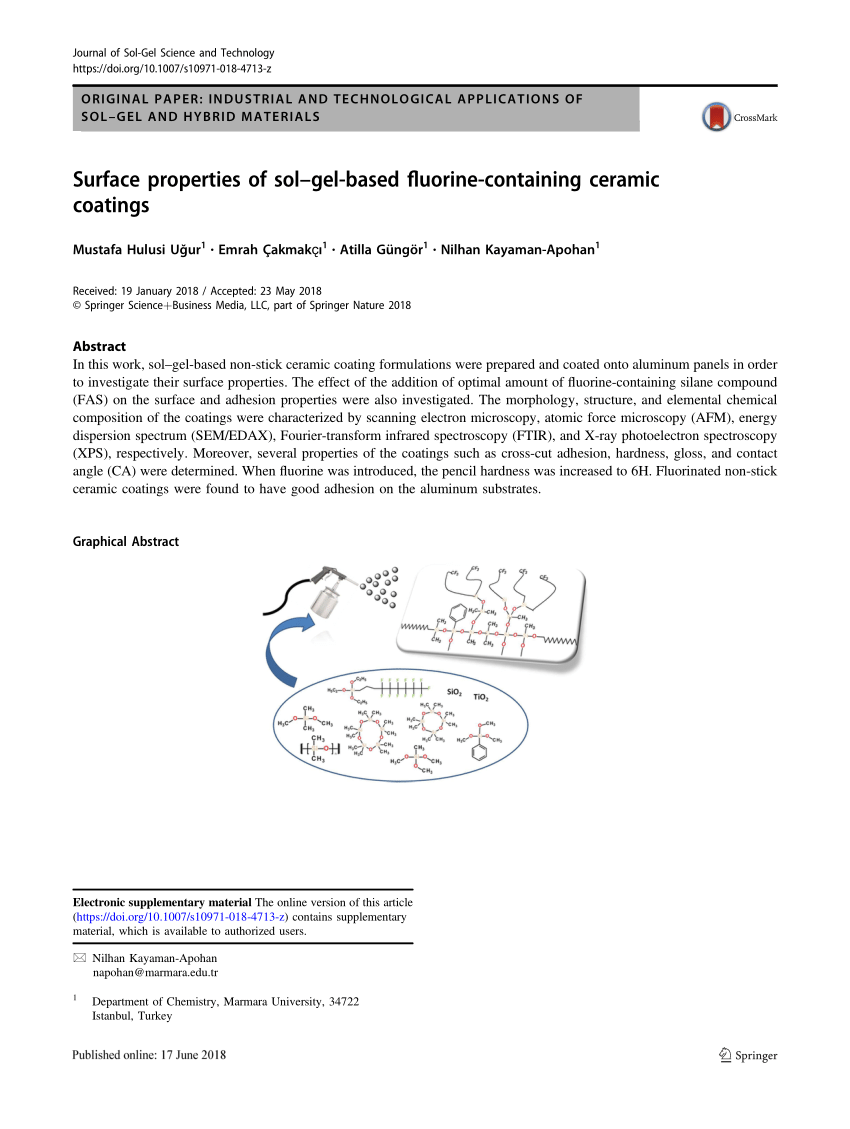

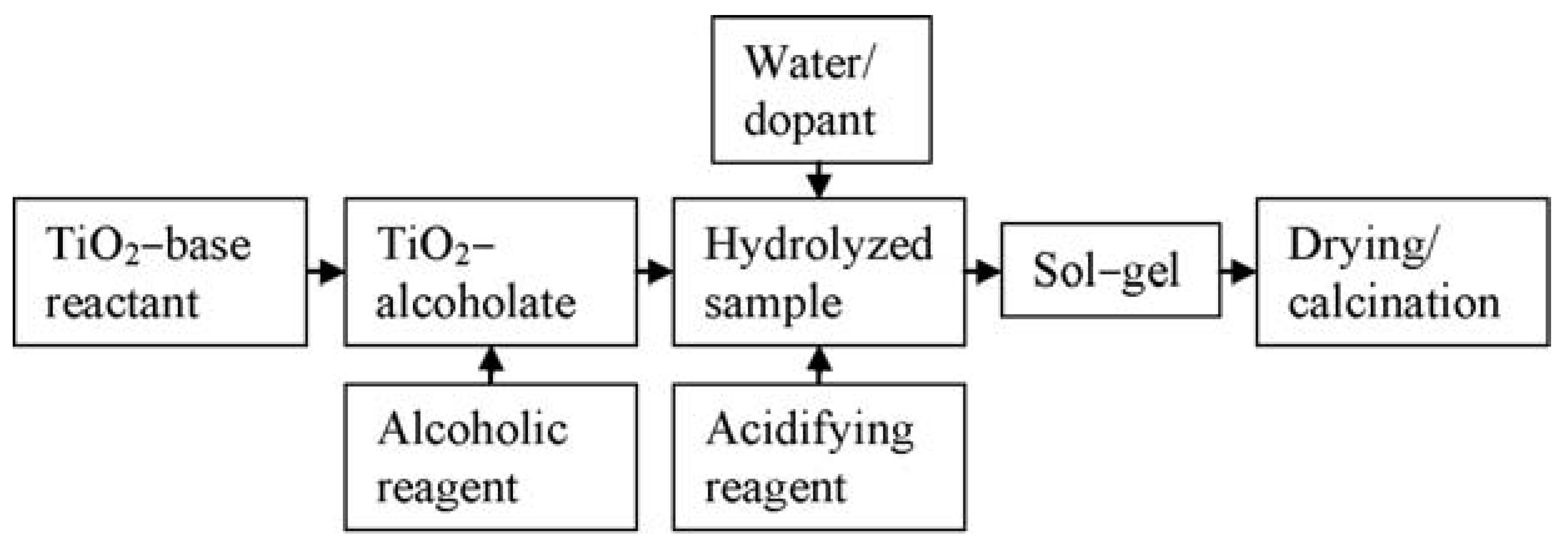

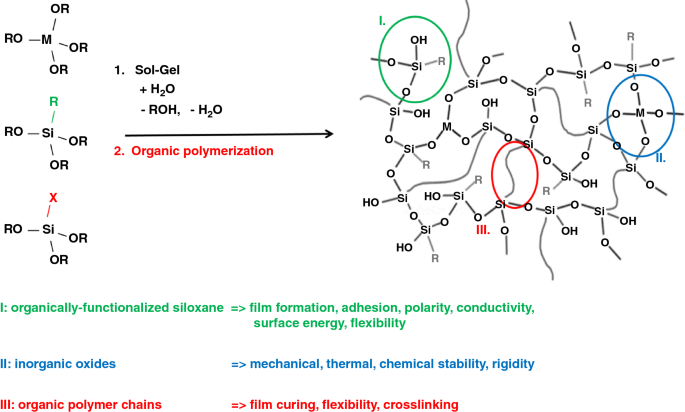

So gel process for ceramic coatings. Likewise sol gel reactions do not employ extreme reaction conditions. Sol gel coatings may be deposited on metals to improve their resistance to oxidation. Sol gel is a process where solid materials are produced from small molecules. Sol gel coatings are in fact hybrid coatings and usually have 2 or more parts that are mixed to reach the ultimate coating.

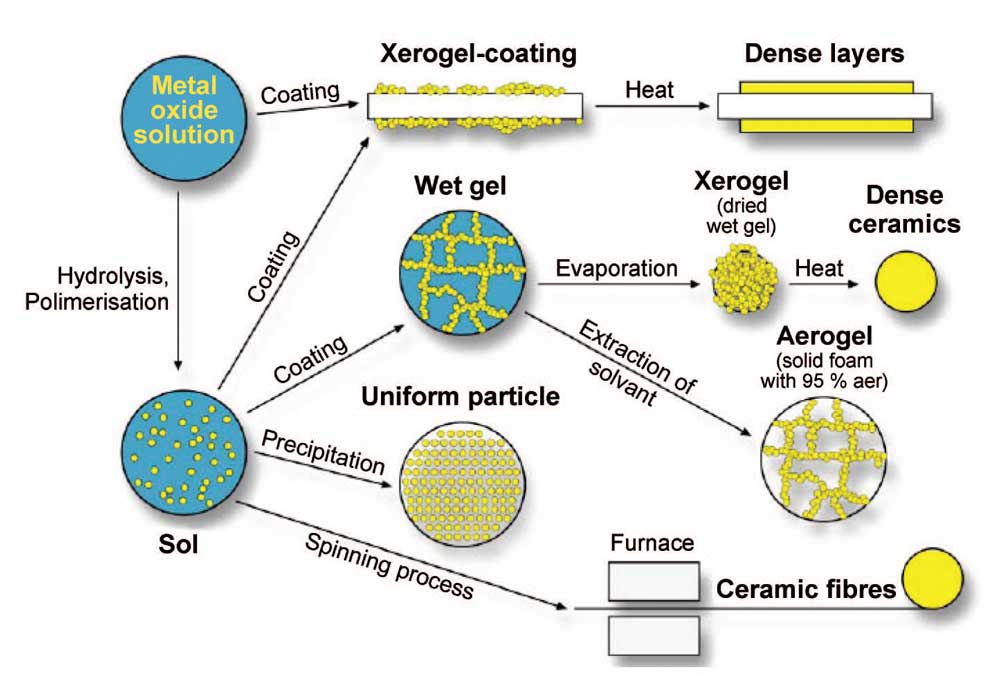

Sol gel processing is beneficial in the formation of ceramic and glass films for many reasons. They may also be used to tailor the chemical properties of substrate surfaces. The preparation of optical coatings by spraying offers several advantages compared to the dip coating technique since the so far realized processing speed of 1 m min is already 10 times faster the waste of coating sols is much smaller coating sols with rather short pot lives can be used and the coating step is suitable for establishing an in line process. The sol element of sol gel is a solution in which particles are suspended.

Ceramic nanoparticle were discovered in the early 1980s. The sol gel process is a method used to make solid materials from small molecules. Sol gel coating is a way to create single or multicomponent oxide coatings on glass or metals. A spin coating method for one sided sol gel coating or dip coating for double sided coating.

The sol gel process is a wet chemical technique used for the fabrication of both glassy and ceramic materials. For sol gel coating there are basically two methods. Sol gel method has about three decade long history starting with processing of oxide materials including glass and ceramics in early days to preparation of non oxides as well in the recent times. The process handles the transformation of monomers into a colloidal solution the sol that acts as the forerunner for an integrated network the gel of either discrete particles or network polymers.

Processing of organic inorganic hybrid nano composite materials using this technique is now an active field of research. Sol gel coatings may be used for surface planarization in multilayer microelectronics processing and for electronic passivation. So for instance a one layer sol gel coating consists of 2 or more parts that are mixed to achieve the final result. The material is so small that it has basically no flaws.

Later methods involved sintering pressure and heat. The suspended particles undergo hydrolysis through the addition of water and subsequent condensation polymerisation where molecules join together and form a gel where the gel element of sol gel comes from. In this process the sol or solution evolves gradually towards the formation of a gel like network containing both a liquid phase and a solid phase.