Snap Fit Flooring 45 Angle

Thick snap flooring has specially shaped tongues and grooves that interlock to form a strong tight joint without glue or nails.

Snap fit flooring 45 angle. 316 8 flexing elements references on page 362 loss of retaining force in the case of snap fit elements that are repeatedly joined and separated or those that remain. Prosource fit extra thick puzzle exercise mat 3 4 or 1 eva foam interlocking tiles for protective cushioned workout flooring for home and gym equipment 4 6 out of 5 stars 1 952 45 99 45. Lee alan dubin and elmer d. Compare click to add item snapstone 6 x 24 interlocking porcelain floor tile to the compare list.

How to fix seam separations in glueless snap together laminate wood flooring. Jones short cantilever beam deflection analysis applied to thermoplastic snap fit design 1987 spe. The laminated flooring in this project has a soundproof backing and textured cherry wood finish. The history of the flooring industry is ripe with examples of innovations intended to make floors easier and faster to install and nowhere is this more true than for ceramic and porcelain tile up until 50 years ago ceramic tile was always laid into a thick layer of wet mortar reinforced with metal mesh a method that made for a very durable floor but one that was very hard to remove and.

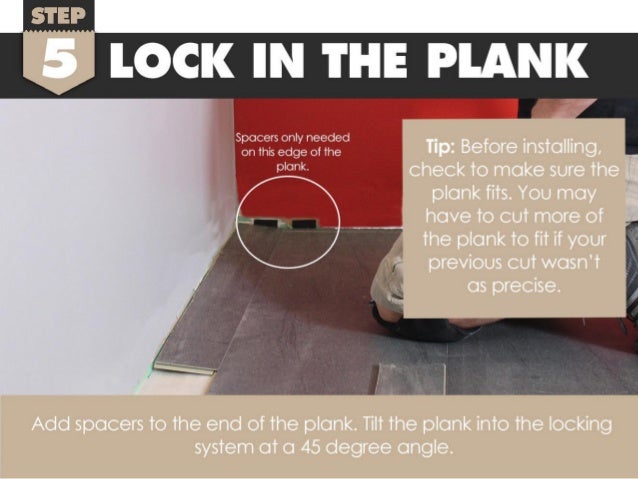

Click to add item snapstone 6 x 24 interlocking porcelain floor tile to the compare list. It snaps together by lining up the planks at an angle and then flattening out the row being installed image 2. To a point the greater the angle the greater the holding strength of the snap. Figure 8 10 forces and moments acting on a snap fit hook having a retaining angle of 90 at the time of release 8 1 snap fit joints.

The flooring we re using for installing laminate flooring is similar to snap together plastic laminate floors except that it has a surface layer of real wood. Snap fit design examples 1 2 illustrate this procedure for designing snap fits including calculating the maximum strain developed during assembly and predicting the snap in force required. It snaps together by lining up at an angle and then flattening out the row being installed. To save the edges of the flooring boards use a tapping block or rubber mallet to tap adjoining rows together image 1.

The integrity of the assembly can be improved by increasing the overhang depth. The laminate flooring in this project has a soundproof backing and wood finish. This is true only up to the shear strength of the snap and the effects of bending moments applied to the beam while assembly is equal to overhang depth of beam.

/cdn.vox-cdn.com/uploads/chorus_asset/file/19495909/h1006handbook08.jpg)