Smallest Safe End Mill For Hardwoods

Single and two flutes for clean burr free finish.

Smallest safe end mill for hardwoods. Besides requiring replacement a compromised cutting tool can produce subpar results and scrapped parts. Definitive guide to feeds and speeds for wood updated for 2019 cnc feeds and speeds cookbook. Generally speaking more flutes on an end mill means a smoother edge finish. Larger mills can remove a lot more material than smaller mills.

End mills come in varying shapes and sizes for accomplishing different cutting functions. Here s your comprehensive guide to feeds and speeds for wood together with tips and techniques that are specific to cutting wood on a cnc machine. 10 pcs 4 flute end mill bits afunta 0 08 0 47 hss cnc straight shank drill bits cutter tool set for wood aluminum steel titanium 4 4 out of 5 stars 753 15 99 15. More flutes also means there is a smaller surface area to eject cut chips away from your stock material.

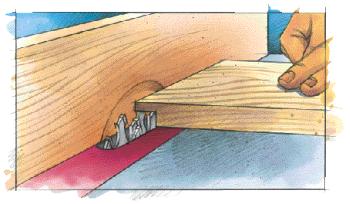

An end mill is a kind of milling cutter that is connected to the spindle of the milling machine. Downcut end mills prevent workpiece lifting lessen burrs and top surface chipping improves surface finish. End mill sets tungsten steel cnc router burrs end milling engraving bits drilling hole tool for pcb circuit board plastic fiber wood copper 0 5 3 175mm set of 12 4 4 out of 5 stars 115 21 99 21. For instance some have huge tools to remove more material faster while others have small teeth for finer finishes.

Manufactured in house with many tools in stock ready to ship. You ll commonly find two flute wood cutting mills in diameters of 250 375 and 500. Premium ultra fine nano grade solid carbide for maximum tool strength and durability. This means you will need to use a slower feed rate so the bit has time to properly dispose of the cut materials.

For the purposes of using a cnc to cut parts out of wood you ll want to use larger mills wherever possible. They offer two small personal sized mills for small weekend jobs four professional sized mills for increased production using larger logs and industrial strength bandsaw mills that can match circular saws in productivity. Few things can ruin a machinist s day more easily than a broken chipped or prematurely worn down end mill. Standard and metric size end mills.

No other company can match wood mizer s selection of mills.